TPE, also known as thermoplastic elastomer, is a soft rubbery material which can be injection molded, extruded, and blow molded, and can be completely bonded with hard plastics such as PP, ABS, PS, PC, and PA.

1、wire and cable Mainly used for wire, mainly for charging pile cable, also widely used in automotive wiring harness sheath, data cable plug connector, automotive interior parts and other combustion products. This product has excellent comprehensive performance: soft touch and gentle texture, UV resistance, acid and alkali resistance, high temperature, flex resistance, ozone resistance, chemical resistance. Moreover, it has excellent elasticity due to its fine and stable processing.

2、auto parts TPE elastomers in the auto parts market is becoming more and more widely used, can be used for soft cushions, storage boxes, air conditioning vents, airbag cover, steering wheel outer cover and so on. Soft touch in dry or wet conditions have good anti-slip performance. Low odor, high temperature aging resistance beautiful appearance, smooth feel.

3、Medical Packaging Materials With the development of science and technology, there are more and more requirements to meet the non-toxic and odorless requirements of food grade and medical grade products. They can be used for infusion tubes, oxygen masks, medical gloves, infusion bags, protective braces and so on. Our TPE meets the test requirements for medical products. Translucent and transparent varieties are available, free of rubber and PVC, and several USP VI certified varieties are available.

4、food packaging according to the market food-grade products are non-toxic and tasteless and sealing requirements, our company after years of research and development to meet the requirements of food packaging tests, can be sterilized at high temperatures, can be customized to replace the traditional low specific gravity foaming products, can meet the conditions of high-temperature heat and humidity sterilization sealing excellence. Can be used for oral liquid, bird's nest health care products plugs, water cups, fresh box sealing strip, coffee machine cups of glue.

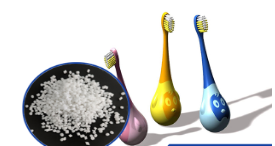

5、Toolkit adhesive In order to meet the requirements of consumers for soft-touch type handle, our company developed a series of TPE wrapping material, which can make the product become comfortable to the touch, firmly bonded, with anti-impact, shock absorption, anti-slip function. Mainly used for automobile handles, medical toothbrush handles, game handles, power tool handles, industrial paint brushes, medical trolley casters and so on.

6、Electronic appliances, communication equipment miniaturization and personal characteristics of the increasingly obvious trend. Our research elastomer feel soft, beautiful appearance, shock absorption and anti-slip in line with the best touch of human skin. In the radio bluetooth headset, cell phone anti-slip jacket shell, switch plugs, data lines, camera parts in a very wide range of applications, greatly improving the competitiveness of customer products.

7、Daily life the use of high-quality imported raw materials, safe, non-toxic, odorless with excellent resilience and shock absorption and excellent non-slip performance. Suitable for non-slip mats, yoga mats, watch bands, cosmetic cases, toothbrush handles, cutlery mats, pillow cores, mattresses and so on.

8、high-grade shoe materials can be used in ordinary injection molding machine injection molding, lightweight products, good rebound, good weather resistance, not cracking; good bending resistance, not bottom; shock absorption effect, soft and comfortable; waterproof, anti-slip, acid and alkali resistance, excellent low temperature resistance; shrinkage stability, not easy to deform after shaping, without glue and fabrics in one molding. It can be used to make toes and soles, massage insoles, uppers and vamps, sports shoes and casual shoes.

9、stationery, toys, infant toys TPE toys and stationery for transparent translucent and natural color particles. With a soft and comfortable feel, beautiful and lovely appearance in line with the best touch of human skin, safe and environmentally friendly non-toxic and odorless. Can be used for pen sets, erasers, staplers, toy car tires, game console handle, Barbie, yo-yo, pet toys and so on.

With the increasing demand for environmentally friendly, comfortable and high-performance materials, the application prospect of TPE is very broad. In the future, TPE materials will continue to innovate and develop, and play an important role in more fields. For example, in the medical field, TPE can be used to make medical devices, prosthetic limbs, etc. In the aerospace field, TPE can be used to make seals, shock absorbers, etc. At the same time, with the progress of technology, the performance of TPE will continue to improve, the cost will continue to reduce, to provide strong support for its wider application.

If You Have Any Questions Or Needs About The Product, Please Fill In The Following Form And We Will Contact You As Soon As Possible.

LOOKING FOR

MORE INFORMATION?

Email:

nate.chen@shixintongda.comAddress: Room 607, Building B, Sunkin Center, 2 Jiulianshan Road, Huangdao District,Qingdao, Shandong, China.

This website stores cookies on your device. These cookies are used to collect information about how you interact with our website and allow us to remember you. We use this information in order to improve and customize your browsing experience and for analytics and metrics about our visitors both on this website and other media. To find out more about the cookies we use, see our Privacy Policy.